By Howard Ellegant, AIA, CVS-Life, FSAVE

A Value Study is About Changing the Conversation

The power of a modern Value study is its systematic approach to changing the conversation from a focus on the physical item or process being studied to a discussion of its purpose(s) or as Miles called them, functions. This changed conversation takes place through the mechanism of Function Analysis, identifying and analyzing functions or, what customers NEED and WANT to make facilities, projects, products and processes work for them and at what cost. For simplicity I refer to the facility, project, product or process reviewed in a Value study as “the project.”

Without Function Analysis, whatever the effort is, it is not a Value study. FAST may seem slow but it focuses the team’s energy, creates a common language for the team, deepens team understanding of the problems to be solved and jump-starts the creative process. Customer Oriented Function Analysis and FAST changes the conversation to focus on overall project value to the customer not just high costs.

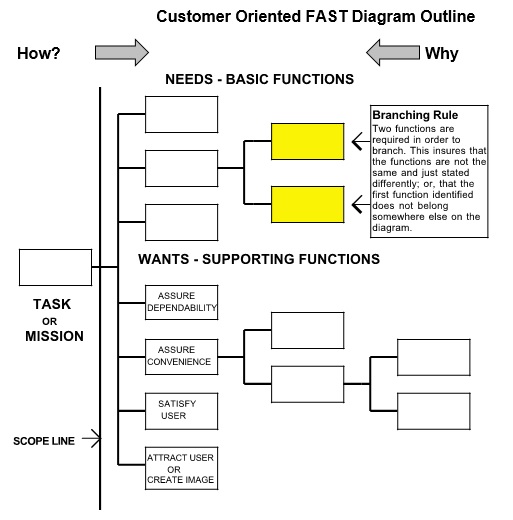

This article does not discuss construction of a Customer Oriented FAST Diagram. The emphasis is on how it is used to identify poor value functions from the perspective of the customer. The essential elements of the Customer Oriented FAST Diagram are highlighted in Appendix 1.

How it all started

Larry Miles, the acknowledged father of Value Analysis/Value Engineering (VA/VE), articulated the idea that “the customer wants a function” – that is “(H)e wants something done. He wants someone, perhaps himself pleased. He wants something enclosed, held, moved, separated, cleaned, heated, cooled or whatever under certain conditions and within certain limits; and/or he wants a shape, a color, an aroma, a texture, a sound, a ‘precious’ (costly) material, or whatever to bring pleasure to himself or others he wishes to please. That is all he wants. That is all he cares about.” – Techniques of Value Analysis and Engineering, 3rd Edition; Miles, Lawrence D.; p25

Marshall Field, the 19th Century Chicago department store magnate is reported to have said, “Assume that the customer is right until it is plain beyond all question he is not.” He was all about giving the customer what he or she wanted.

I put these two quotes together because they recognize the customer as the center of the buying experience and the need to satisfy the customer’s requirements that Larry Miles called ‘functions’. The merchant, sales person, supplier, or designer responds to customer requirements with a product, process or design to fulfill those requirements or functions.

Miles also said that customer requirements, or functions, can be defined with only two words, an active verb and a measurable noun. This forces conciseness, preciseness, and clarity and deepens understanding of customer requirements. Finally, Miles’ pre-eminent guiding principle of VA/VE: “All cost is for function.” So, the customer wants a function; fulfilling customer functions has a cost; and, the customer is right until he is not. How does a Customer Oriented Value Study and Customer FAST apply all of this?

The early days of Value work

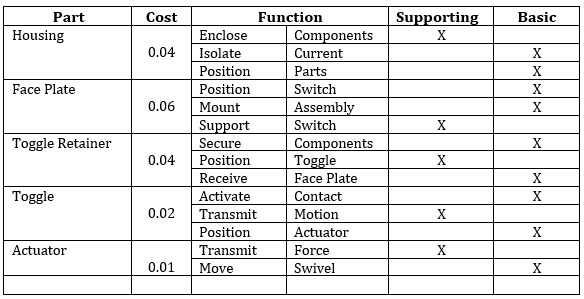

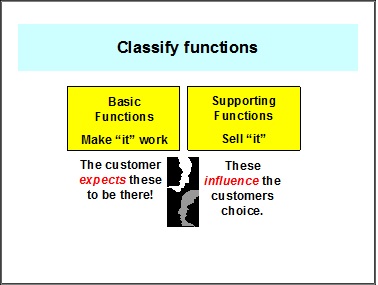

In the formative days of VA/VE, teams of people with expertise in design, procurement and fabrication looked at the parts of a project, asked what function(s) each performed, and listed the verb-noun function answers in a matrix including whether the function was Basic (necessary to make the part work) or Supporting (modified how the Basic function was performed.) (Fig 1). The team then asked if the functions could be performed differently and for less cost. If there was a less cost alternative to reliably performing a part’s function(s), the functions were deemed to have poor value. Poor value functions were carried into the Creative Phase of the Value study where the question, “How else can we perform the function(s)?” led to lists of alternative materials, methods and processes to be evaluated in a later study phase.

Fig 1. Partial Matrix Function Analysis Example – Mechanical Light Switch

Origin of FAST

Charles Bytheway conceived the idea of writing verb-noun functions on pieces of paper and organizing them in a How?-Why? cause and effect sequence in order to deepen his understanding of the problem to be solved. The essential question, asked later, was still, “How else might we perform the function?” Practitioners expanded on Bytheway’s idea and formalized the organization of functions into the diagramming system we know as FAST – Function Analysis System Technique. Function identification and construction of the FAST diagram, indeed the entire Value study, was still carried out by a team of people with technical knowledge about how the study object was designed, parts procured and fabrication accomplished.

In a Value study using a team of technical experts, value was determined by analyzing the relationship between Function Worth and Function Cost. (FunctionValue = FunctionWorth/FunctionCost) The team of technical experts had the capacity and the data to determine the cost of the study project. Worth was determined by the value study team of experts suggesting alternative ways to reliably perform a function. If the alternative to perform a function cost less than the design being studied the function was said to have poor value. But was the technical team performing the study the best arbiter of value?

Who determines value?

According to Miles, “A product or service is generally considered to have good value if that product or service has appropriate performance and cost. Or, by reverse definition, a product is considered not to have good value if it lacks either appropriate performance or cost.” – Techniques of Value Analysis and Engineering, 3rd Edition; Miles, Lawrence D.; p5

Is it good value? Ask the customer. It doesn’t make any difference if the seller, designers, contractor, manufacturer or anyone else in the supply chain says it’s good value! The customer is the only person whose opinion counts. One more time, the customer is the only person whose opinion about value counts. Good value? The customer will part with hard earned money to buy. Poor value, no sale or no more sales to that customer or anyone to whom the customer relates a bad buying experience, i.e. receiving poor value for money.

Companies and organizations have for years conducted market research in order to determine potential customer attitudes toward new or existing products and services. Panels of likely or actual customers are convened. A facilitator asks pre-determined questions to illicit responses about the likelihood of use, purchase and price of whatever product or service is the focus of the research. The results are collated and analyzed and turned over to the technical people to inform their design.

The Customer Oriented FAST Diagram

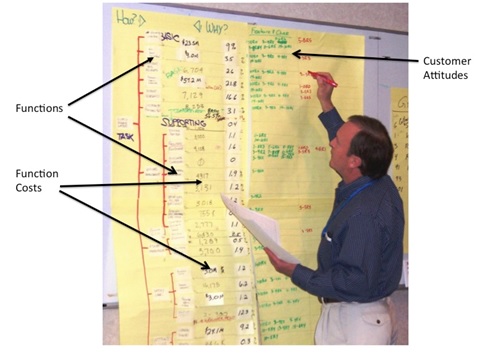

In the Value Methodology community Prof. Thomas Snodgrass and Theodore Fowler were the first to think it necessary to ask the customer to help determine whether functions had good or poor value. Snodgrass and Fowler evolved, practiced and promoted the Customer Oriented FAST Diagram (Fig .2). Its unique characteristic is that it displays on a large diagram functions, the cost of the functions, and customer attitudes about function importance.

Through discussion of functions, their costs and their importance to the customer, the team develops consensus about whether functions have good or poor value! Only poor value functions from the customer perspective are carried into the Creative Phase of the Value study to be reviewed for alternative ways to perform them. Note that functions are not judged solely by their cost. Both high cost and low cost functions are reviewed for their value. Customer attitudes related to the functions leads the team to determine some high cost functions represent good value to the Customer. Conversely, some low cost functions represent poor value.

Fig 2. Customer Oriented FAST Diagram

Value Mismatches

The last activity of the Information Phase in a Customer Oriented Value Study is identifying Value Mismatches. The charge for the team is to determine which functions whose cost, whether high or low, do not match customer perception of their performance or importance. Think of a Value Mismatch as a target of opportunity to help improve overall project value to the customer. Miles noted:

- “Value is always increased by decreasing costs (while of course maintaining performance.)

- Value is increased by increasing performance if the customers needs, wants, and is willing to pay for more performance.” – Techniques of Value Analysis and Engineering, 3rd Edition; Miles, Lawrence D.; p5

The first activity of a Customer Oriented Value Study is to gather customer attitudes about the various features and characteristics of the project. But who are the customers? Depending upon the study project, customers may be internal or external to the organization conducting the study. Customers may be end users, distributors, suppliers, factory floor workers, field people, managers, process operators, etc.

A panel of 10 to 12 customers and providers (those who design, build, market, service the project) is convened. The panel is asked two questions: First, what are the features and characteristics of this project and how important are they to you? Second, what don’t you like about the current design and how big a fault or problem is it? Panel members first discuss the features and characteristics and then the faults and problems. They are asked to reach consensus on the most important item within each of these two groups. What is the most important feature and characteristic you can’t live without? And later, what would be the biggest problem or disaster if the fault of problem were not corrected? Panel members discuss the items and rate on a scale of one to ten the relative importance of each item within each group as compared to the “can’t live without” feature and characteristic and then the “it’s a really big deal” if the fault or problem is not corrected. Specific features and characteristics and faults and problems are recorded, and eventually in a coded form are posted on the FAST diagram in separate columns under the Customer Attitudes heading. Features and characteristics are written in green, faults and problems in red. (See Fig 2)

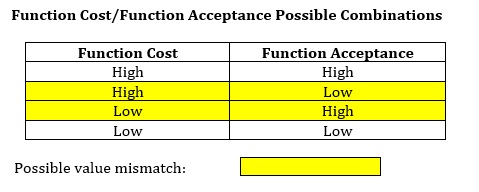

To determine the Value Mismatches, team members are instructed to individually review the FAST diagram and select functions that are possible Value Mismatches using guidance in Fig 3 below. Obvious value mismatches are most likely the highlighted Function Cost/Function Acceptance combinations. Team members may also direct their attention to high function cost and high function acceptance functions with an eye toward trying to reduce cost, but maintaining required performance. Generally low function cost/low function acceptance functions are put on a back burner under the, “If it ain’t broke, don’t fix it” heading.

Fig 3. Possible Value Mismatches

Each team member is given five “sticky” red dots. After thorough discussion each team member votes by placing one or more of their five red dots on any function(s) judged by them to be a mismatch. Value mismatched functions are carried into the Creative Phase of the study prioritized by the number of votes each receives. Functions with the highest votes are first reviewed for alternative ways to perform them followed by the next highest, etc.

The Value study then continues as usual through the remainder of the Creative, Evaluation, Development and Presentation Phases.

Advantages of the Customer Oriented FAST Diagram

The Customer Oriented FAST Diagram brings the voice of the customer into the value study helping the study team focus its time and energy where it matters most to the customer. Proposed changes are met with positive feedback from the customers since study results respond to their primary concerns and align with customer perceptions of the project end use.

The customer is involved in the study process from the beginning through participation in the panel that collects their attitudes about important project features and characteristics and faults and problems that need to be avoided or corrected. This creates customer ownership of both the study and its results.

Identifying Value Mismatches focuses the team on overall project value improvement. This means not only identifying where money can be saved but also where savings can be invested in project improvements if the budget permits.

Appendix I

Three kinds of functions are identified in Customer Value studies.

Task or Mission – The single function that fulfills or meets the overall need of the customer. The task is the overall reason for the project or product existence. It is the highest order function and grows out of the Basic Functions.

Basic Functions – Those functions Needed to make the project, product or service work and thus accomplish the Task.

Supporting Functions – Wanted functions that sell the project, product or service. They are not necessary to make the project, product or service work or to directly accomplish the Task or Mission. They increase customer acceptance. The all important “buy” decision is seldom influenced by the Basic Functions, or Needs. The customer’s perception of how well WANTS are satisfied influences acceptance of a project, product or service. The bulk of total costs accomplish the Supporting Functions, and represent fertile areas for value improvement that improve total customer acceptance. Supporting Functions are sorted into one of four types – functions that Assure Dependability, Assure Convenience, Satisfy User or Attract User.

Classifying Functions

Supporting Function Definitions

The following definitions for the four given Primary Level supporting functions are for general guidance to assist in determining where on the diagram to place the supporting functions defined by the team. The most important distinction to make is between Basic and Supporting Functions. Once the determination has been made that a function is a Supporting Function, the specific primary Supporting Function to which it is assigned is of lesser importance.

Assure Dependability

- Protection of persons, operations, products,

- Reliability of operations, Compliance with special regulations, codes, laws

- Extending life of systems

Assure Convenience

- Aids in cleaning, servicing repairing

- Ease of accessibility

- Reduction in travel, processing or communication time

Satisfy User

- Modifies Basic Functions: faster, smaller, lighter, variations

- Degrees of physical comfort

- Appeals to status

- Life cycle cost considerations

Attract User

- The visual or aesthetic aspects only

- Overall appearance

- Decoration

- Creating or matching context

- Implied performance: sturdy, fast, safe

Checklist for Customer FAST diagrams

- Basic and Supporting Functions clearly separated?

- Left scope line shown?

- How? – Why? arrows shown?

- Only one Higher Order function to left of scope line?

- Minimum of two functions to branch?

- No function repeated twice?

- Does the “How? – Why? logic” check?

The bottom line: does the diagram communicate project purpose?

Appendix II

Suggested Reading:

- Function Analysis and Quality Management, Prof Thomas F. Snodgrass, CVS, FSAVE – 1993 SAVE Conference Proceedings

- Determine Value Mismatch by Measuring User/Customer Attitudes, THOMAS F . Cook , CVS, FSAVE – 1986 SAVE Conference Proceedings

- Back to basics – Only Complete Client Centered Function Analysis Makes

- Legitimate VALUE Engineering in Construction – Howard Ellegant, AIA, CVS, FSAVE – 1989 SAVE Conference Proceedings