By Celestine Aguwa, PhD, VMA – Wayne State University; Drew Algase, CVS – Value Management Institute; Leslie Monplaisir, PhD – Wayne State University

INTRODUCTION

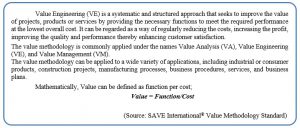

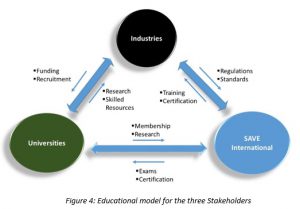

This paper discusses the collaboration among the three main collaborators that most significantly contribute and benefit from the advancement of VE domain as shown in Figure 1; the Universities, SAVE International® and the Industries [governmental organization that use VE (e.g. Army Corps of Engineers, State department, Federal Highway Administration as well as many state and city agencies)].

The universities here are academic institutions comprising of faculty and students who will carry out research and coursework at an academic level in order to satisfy course or degree requirements. SAVE International is the premier international society devoted to advancing and promoting the value methodology. They offer their members education and training, publications, tools for promoting the value methodology, certification, networking and recognition. SAVE is in more than 35 countries. Applications can include construction, product design and manufacturing, transportation, health care, government and environmental engineering.

The Industries refer to any organization which provides products and services, with processes that adopt the value methodology, partly or wholly. It also includes the government regulatory agencies that decide the norms with which the industries operate. The industries create the demand for value engineers and are potential employers of the skilled value engineers, improving the value of their product. This a framework for a future work on the quantitative analysis of the VE education model [1], [2], [3].

Figure 1 shows a collaboration of USI to instill a sense of VE in all undergraduate and graduate programs enhancing its potential in terms of research and utilization across all fields. This collaboration is explained, in detail, in the following sections; Section 2 represents the motivation and current stance of VE in the academic institutions and its application in the industry and discusses the successful conglomeration of academic institutions, industry and a board for certification of individual value engineers by the SAVE International® Certification Program.

Section 3 explains the proposed implementation plan to form the collaboration, Section 4 represents the contribution by each of the members of collaboration to yield maximum benefit to all, Section 5 discusses the mutual benefits involved to the industry, academic institutions and the certification board in the promotion of VE followed by broader impacts and Conclusion in Section 6 and Section 7 respectively.

MOTIVATION

Intense global competition, rapid technological change, and shorter product life cycles have transformed the current competitive environment ([4],[5] and [6]. Consequently, there are increased pressures on firms to continually advance knowledge and new technologies in order to ensure long-term prosperity and survival [7]). While past practices favored internal initiatives, it is increasingly more difficult for firms to rely exclusively on in-house activities due to limited expertise and resources [8], [9],[10],[11] and [12].

One of the key internal activities VE aims at improving is the quality and processes that are being practiced across all levels in any industry so as to bring about better life cycles and technology in a long term basis. Most VE research has been carried out by academics, research students and research organizations. The growth of research in this subject generally has coincided with the development and expansion of undergraduate and graduate credits in value engineering and related disciplines together with the need to underpin students learning[13]. It will also help develop the coming generations to lead and take over the institutes doing in the coming years.

We also notice the rise of representation of different student organizations such as Industrial and Systems Engineering (IISE) and Six Sigma in various graduate and undergraduate programs in Universities that further strengthen awareness of these domains. The IISE organization in Montana University organizes tours of local businesses, manufacturing facilities and brings guest speakers from industries. It provides a way to meet and make a bigger network with other engineers and also helps to improve the leadership skills along with volunteering skills. Furthermore, the proposed model can be justified by the apparent disconnect between academia and industry in terms of effective training and certification in VE.

PROPOSED COLLABORATION MODEL

The proposed implementation plan can be explained below in terms of overall architecture and a description of a value engineering program that can execute the architecture.

Proposed Architecture

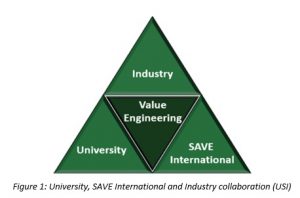

The proposed architecture is shown in Figure 2.

The above architecture signifies that students who graduate from the universities are responsible for carrying the knowledge obtained from USI back to the industries and also contribute towards the research and development of VE.

SAVE International is a global agency that certifies the students and industrial associates in value engineering. A detailed working of a program that can execute the architecture is as mentioned below.

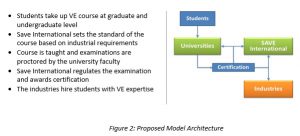

Value Engineering Program

A program consisting of basic working functions between the industrial and systems engineering and SAVE international is proposed. The program briefly describes how the collaboration can be executed by describing the workflow. The industrial and systems engineering department in the universities and SAVE international are jointly involved in determining the level of training to perform as a Value Methodology Associate (VMA) and standard of VE education for graduates and undergraduate students in the universities. The universities provide necessary training to graduate and undergraduate students by offering course credit also preparing them for a VMA certification examination which is administered by SAVE international. The examination is proctored at the universities at the end of the training course or semester and a VMA credential is awarded to the students who satisfy the requirements that are set by SAVE.

In addition to the above, the students and faculty at the Industrial and systems engineering can contribute towards the research study based on the requirements from the Industries. The Industries can employ the graduates and undergraduate students who are now skilled and certified in VE.

CONTRIBUTIONS

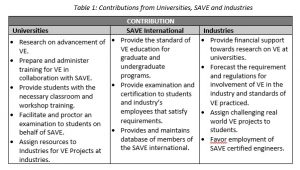

The contributions of USI are briefly mentioned in the table 1.

VE is an upcoming area of importance due to its capability to reduce total cost of any projects without compromising on the efficiency and quality. It is thus being offered as an academic program in various universities such as Wayne State University, McGill university, Howard University, University of Tennessee and Syracuse University etc. [14]

Universities can prove to be an integral part in contributing to the growth of VE practices thereby aiding to provide more VE solutions for a variety of problems that may exist or arise in the current industries. Universities can benefit many ways in which VE is being practiced. Alternate ways of solving problems can be obtained from universities as ideas from new graduates can be utilized. According to Richard Lambert of University of Illinois, business-university collaboration has three objectives [15]:

- To illustrate opportunities arising from changes in ways that business undertakes R&D and that universities are collaborating with business partners.

- To recognize businesses already collaborating with university departments, which are role models for those without university links.

- To offer ideas and recommendations to shape policy. Points out two new trends shaping business world-wide

Universities can serve to be the platform for graduates and undergraduate programs to provide and administer training. It can also aid to present necessary classroom and workshop sessions for students. Universities can also use VE to streamline their own internal processes such as student loans, business processes, parking etc. Universities can conduct exams on VE under SAVE administration to certify students as “Value Methodology Associate”, facilitating industries to absorb more resources without hesitation.

SAVE International can set the standards for which graduate and undergraduate students should be trained, conduct exams, and certify students to validate the quality of the program. They also maintain the database of SAVE members to establish a platform for networking and progress in the VE front.

Industries on the other hand fund the universities to assist research on VE, forecast the regulation that are to be followed across various industries. They are also encouraged to assign more real world challenges to students so as to accustom prepare their acumen and also find new and creative solutions to their own challenges.

BENEFITS FROM THE COLLABORATION

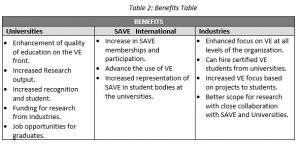

Collaboration of USI will in turn assist each of its members to gain access to more knowledge, exposure and also methodologies to find solutions of scenarios that one might encounter. The possible benefits of each member are as tabulated below.

Benefits to the Collaboration Members: A wide range of benefits follow the USI collaboration. The key benefit to the Universities include increased scope and support for research in the VE domain. They can now ensure and enhance the quality of VE education and training provided as a part of their academics. Hence an increased research output and value of a VE program. It directly benefits the graduate and undergraduate students as they will be certified “value methodology associate” by the end of the course, which by far, is only possible by subscribing to a stand alone certification course.

SAVE International acts as the certification agency to this program and hence gains the benefit of increased customers and membership. Every student who will take the certification will be motivated to be a life member of SAVE and participate and contribute on the long term. It also ensures representation of the international body at a university level through formation of possible student body associations.

Industries are the ultimate beneficiary from this collaboration. They can confidently hire value engineers who are certified by a well established accredation agency, The SAVE International. This assurance will mutually benefit the industries and the students that are seeking employment. They are assured that the certified VE engineers are capable of its application towards the betterment of their products. They are also allowed to outsource their challenges to the students to receive their creative ideas.

The industries also largely benefit from the progress in VE as it enables technology improvement and best alternatives in improving the value of any product, process or services.

The Figure 4 below shows the educational model for the three stakeholders (USI).

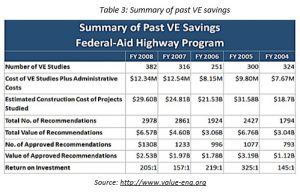

VE also benefits any industry or organization in a way to reduce the overall cost that will be expected to complete a random project. Therefore every government funded project makes it a necessity to use VE. An example of Federal Aid Highway program showing the summary of VE savings as shown in table 3 below;

Improvement in terms of quality cost and delivery: VE primarily aims at increasing value of a product or services by increasing the value of a function while also reducing the cost. VE divides every project or process to various functions and acts to improve the value of each function. This includes reduced accumulation of wastes, effective use of resources, and improvement of quality and cost minimization.

SAVE International is the regulatory and principal authority in matter regarding VE. It serves as the prime body to monitor and check various processes and projects to practice VE. Thus every industry who wish to pursue VE will need to follow certain standards which can be ascertained by SAVE so as to bring in an international benchmark to every activity.

Financial Implications by VE: Many practical scenarios can be stated as an example of cost savings that was brought about due to the practice of VE like sports complex built by U.S army corps of engineers, Napa valley flood control, Mega corp. re-branding, Port of Miami tunnel project etc. Therefore these projects itself stand as a proof to presume that practicing VE can help industries and organizations in cost saving[16].

Table 3 shows various VE studies that are carried out from financial year 2004 to 2008 in federal aid highway program. It is evident from table that following VE would guarantee a return in investment and a percentage of invested amounts can be saved using VE.

BROADER IMPACT

Value engineering primarily aims at improving the value of any product or processes by reducing the cost of production or by effectively using the resources. VE is thus a practice that concentrates on a long term effect rather than an immediate change. VE on a long term will help ensure proper resource utilization ensuring long term availability on a longer term considering all resources on our planet are limited. It will also help bring about a long term cost benefit to any product or service due to wise utilization of resources. As VE is more focused on apt utilization, it will compel progress in innovation in technology to bring large benefit to our environment and ecosystem.

VE awareness also helps identify and motivate the underrepresented and minority groups to apply VE to their own lives and benefit from its advantages. This will pose a positive impact on our society and its development.

CONCLUSION AND FUTURE WORK

Value engineering is an area of great significance to the industry, nurturing to the needs by minimizing the cost through reducing raw materials, refining diverse processes and bestowing advanced technology, substituting ones that are obsolete and consequently increase the comprehensive profit. A collaboration of USI can accordingly pave the way to shepherd fresh idea into the miscellaneous disciplines that are a part of the present-day sectors which prove to be the body and frame in amending the destiny of industrial blooming.

The scope of this research proves to be novel and unique to the extent of assimilating the possibility of a successful collaboration among the USI. This throws light on the means to capture this progress and provide a measure to the benefits that can be obtained from this collaboration. A part of future work comprises of research on a model involving a contribution-benefit index that computes the measure of the value obtained from collaboration. A reasonable direction for this work involves recognizing parameters with their respective matrices incorporating Fuzzy logic and Analytical Hierarchy Process (AHP) approach.

REFERENCES

- M.E. Ssemakula, C.A., R.D. Ellis, K. Kim, G. Liao, and S. Shlomo Manufacturing Integrated Learning Laboratory (MILL):A Framework for Development of Core Competencies in Engineering Curricula. International Journal of Engineering Education, 2011. 27: p. 323-332.

- M.E. Ssemakula, C.A., R.D. Ellis, K. Kim, G. Liao, and S. Shlomo Manufacturing Integrated Learning Lab (MILL): A Hands-On Approach to Engineering and Technology Education, in High Impact Technology Conference. 2011: San Francisco, CA.

- M.E. Ssemakula, C.A., R.D. Ellis, K. Kim, G. Liao, and S. Shlomo Manufacturing Integrated Learning Lab (MILL): A Curriculum Model for Hands-On Manufacturing Education’. in ASEE Annual Conference & Exposition. 2011. Vancouver, Canada.

- Ali, A., Pioneering versus incremental innovation: Review and research propositions. The Journal of Product Innovation Management, 1994. 11(1): p. 46-61.

- Bettis, R.A. and M.A. Hitt, The new competitive landscape. Strategic management journal, 1995. 16(S1): p. 7-19.

- Prahalad, C.K., Managing discontinuities: The emerging challenges. Research Technology Management, 1998. 41(3): p. 14.

- Steele, L.W., Managing technology: the strategic view. 1989: McGraw-Hill Companies.

- Hamel, G. and C. Prahalad, Competing for the Future, 1994. Harvard Business School Press, Boston, 1994.

- Jarillo, J.C., On strategic networks. Strategic management journal, 1988. 9(1): p. 31-41.

- Parkhe, A., Strategic alliance structuring: A game theoretic and transaction cost examination of interfirm cooperation. Academy of management journal, 1993. 36(4): p. 794-829.

- Pisano, G.P., The R&D boundaries of the firm: an empirical analysis. Administrative Science Quarterly, 1990: p. 153-176.

- Shan, W., G. Walker, and B. Kogut, Interfirm cooperation and startup innovation in the biotechnology industry. Strategic management journal, 1994. 15(5): p. 387-394.

- Fong, P.S.W. Establishing value engineering as an academic discipline worldwide. in SAVE INTERNATIONAL PROCEEDINGS. 1997.

- SAVE International. http://www.value-eng.org/about_vision_and_mission.php. Accessed October 14, 2016

- Lambert, R. http://papers.ssrn.com/sol3/papers.cfm?abstract_id=1509981. 2003.

- Lawrence Miles Value Foundation http://valuefoundation.org/Educate-Ed-Program.htm n.d. Accessed October 14, 2016

LIST OF FIGURES

Figure 1: University, SAVE International and Industry collaboration (USI)

Figure 2: Proposed Model Architecture

Figure 3: Value Engineering Program

Figure 4: Educational model for the 3 Stakeholders

LIST OF TABLES

Table 1: Contributions from Universities, SAVE and Industries

Table 2: Benefits Table

Table 3: Summary of past VE savings

AUTHORS BIOGRAPHY

Celestine Chukwuemeka Aguwa, Wayne State University

Dr. Aguwa is currently at Wayne State University as an Associate Professor Research involved with research and teaching graduate courses in Industrial and Systems Engineering. His background includes lean and value methodology in product development and advanced manufacturing; voice of the customer analysis in product recalls; decision analysis modeling. He is currently working on several research projects in data analytics which has resulted in several proposals, some of which are NSF and industry funded research projects. He is in collaboration with other faculty working on NSF sponsored research on curriculum development among others. He has a cross functional industrial experience at Ford Motor Company and extensive professional experience as an Architect. Dr. Aguwa has a Ph.D. and MSIE in Industrial and Manufacturing Engineering from University of Pittsburgh and Massachusetts, Amherst, respectively. He also has a B.Arch. degree in Architecture from University of Nigeria. Dr. Aguwa has several awards, including a patent, and has written several published papers. He is a member of the Institute of Industrial and Systems Engineers, SAVE International, INFORMS, Alpha Pi Mu National Industrial Engineering Honor Society, and Beta Sigma Fraternity, International.

Drew M. Algase, Value Management Institute, LLC

Drew Algase is a Value Engineering, 6-Sigma, and Lean Systems specialist. Drew is a director of the Value Management Institute (VMI) of Michigan; an organization specializing in training and facilitation of value improving practices. Drew recently retired from Freudenberg-NOK Sealing Technologies as a Six-Sigma and Lean Systems Master Black Belt. He directed the corporate 6-Sigma (DMAIC & DFSS) and Value Engineering processes, which complement Freudenberg-NOK’s global lean systems program called GROWTTH® (Get Rid of Waste through Team Harmony). Drew has over thirty-five years of engineering and manufacturing management experience with automotive, food processing and consulting industries. Drew is a graduate of the University of Toledo with BSME/IE and MBA degrees. He is a Certified Value Specialist® (CVS®) through SAVE International and a life member of the Institute of Industrial Engineers (IIE). His active service to the VE/VA profession includes serving SAVE International as the Vice President, Global Affairs, past VP of Manufacturing, and past Chairman of the SAVE Certification Board. Drew was elected to the SAVE College of Fellows and is also a director and VP of Operations for the Miles Value Foundation.

Leslie Monplaisir, Wayne State University

Leslie Monplaisir, Associate Professor and Chair of the Department of Industrial and Systems Engineering at Wayne State University (WSU). He is the Lead Researcher and Director of the Product Development and Systems Engineering Consortium (PDSEC) at WSU. His research interests include: Lean Product Development, Design for lean Systems and Services and Design reuse, New Product Technology Decision modeling, Product Architecture Optimization, Design for Supply Chain, Global Product Platform Optimization and Healthcare Technology System Design He has authored over 100 publications in these areas with funded research from NSF, Veterans Administration and Ford Motor Company. Dr. Monplaisir joined the College of Engineering at Wayne State University in the Department of Industrial and Manufacturing Engineering in 1996 from Florida A & M University where he was a visiting assistant professor. He earned his Ph.D. in Engineering Management from the Missouri University of Science and Technology (MUST), a master’s in Computer Integrated Manufacturing from the University of Birmingham in Great Britain.